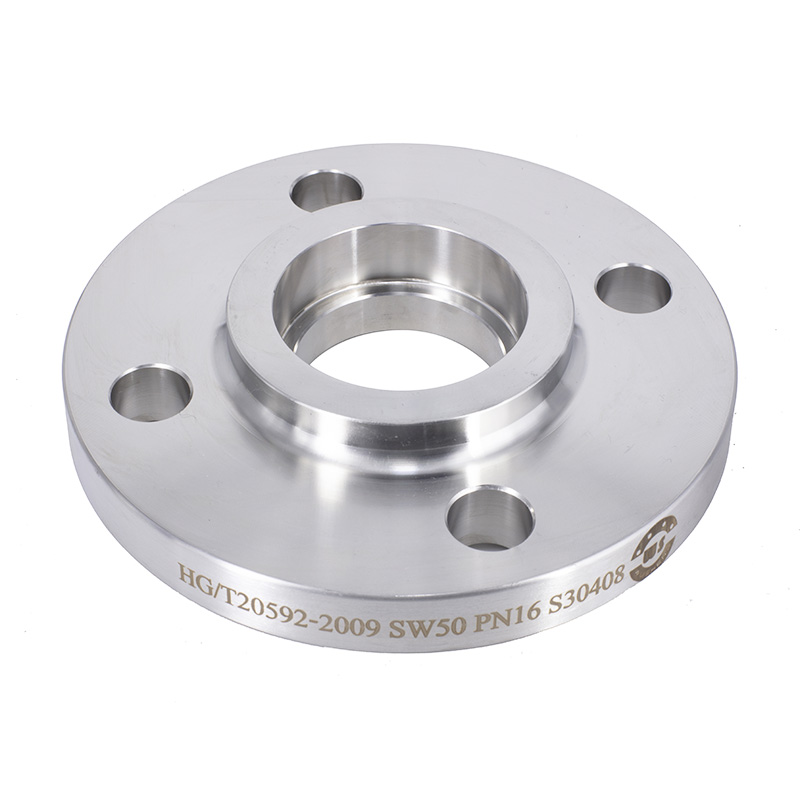

Wusheng 304 Stainless Steel Socket Weld Flanges

Wusheng 304 Stainless Steel Socket Weld Flanges Socket welding flange refers to the pipe end inserted into the flange ring ladder, welded at the pipe end and outside the flange. Available with or without a neck. The flange with neck tube has good rigidity, a small welding deformation, and good seali......

Send Inquiry

Product Description

Wusheng 304 Stainless Steel Socket Weld Flanges Socket welding flange refers to the pipe end inserted into the flange ring ladder, welded at the pipe end and outside the flange. Available with or without a neck. The flange with neck tube has good rigidity, a small welding deformation, and good sealing. It can be used for the occasion of 1.0~10.0MPa pressure. The type B flange of the container is also a socket welding flange, which is used for high sealing requirements. The design of the socket welding flange can be checked according to the whole flange.We can provide a 304 Stainless Steel Socket Weld Flanges price list when we receive the quotation Wusheng is a China S304 Stainless Steel Socket Weld Flanges supplier. Due to the reasonable design of products, advanced technology, reliable performance, and stable quality, the majority of users rely on and praise them.

304 Stainless Steel Socket Weld Flanges are pipe connectors that contain a tube and are welded to a tube. Including the socket in the socket weld flange provides a stronger connection than similar slide-in flanges. Socket weld flanges are designed for small, high-pressure pipes. This type of flange is very popular in chemical plants and requires all flange connections to have smooth flow connections. The advantage of a flange connection is that the pipe can be easily removed from the flange and easily reassembled.

For slide-in flanges, the pipe must be chamfered so that welding can be performed on both the inside and outside of the flange. The internal welds need to be polished to form a smooth, flowing connection. The socket welding flange allows liquid to pass through the connection without crushing. The socket is designed to have an inner lip as wide as the width of the pipe into which the flange is to be inserted. In this way, the tube can be precisely aligned with the lip of the socket in the flange as the unit is assembled, resulting in a smooth transition in the flange.